-

GPU-Based High-Precision Physics Engine

Calculates detailed physical interactions such as robot contact, joint torque, and friction with near-real accuracy, ensuring that programs validated in simulation operate on real robots without collision or singularity issues. -

Domain Randomization

Randomly varies environmental parameters such as lighting conditions, object textures, and sensor noise during training. Through this process, robots learn 'robust' behaviors that can adapt to various conditions, forming the foundation for generating OLP programs that reliably respond to unexpected variables in real-world environments. -

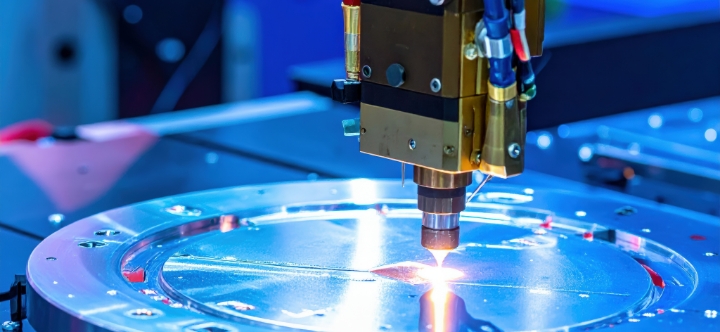

Omniverse-Based Vision Data

Using cutting-edge ray tracing technology to generate visual data nearly identical in quality to real camera sensors, enabling high-accuracy OLP path generation for vision-based robot tasks (e.g., object recognition and handling).

PRINCIPLES

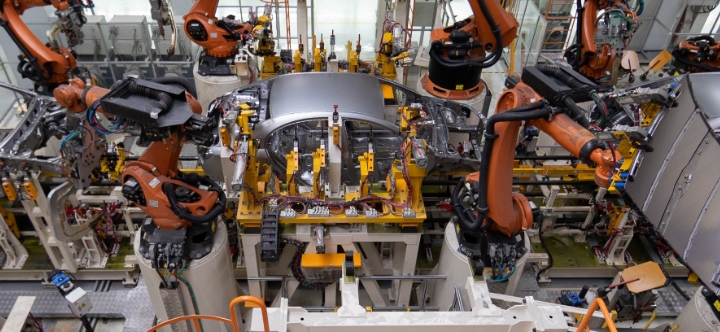

Robot Program Optimization Through Sim2Real

Unlike conventional simulators, this goes beyond simply reproducing robot movements.