-

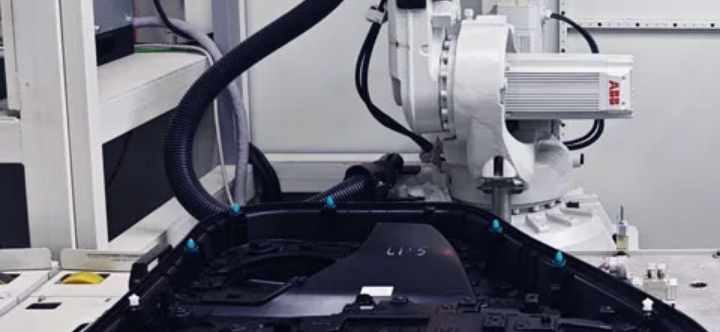

3D Data Acquisition

A 3D sensor (Eye-in-Hand) mounted on the robot gripper acquires 3D shape data (Point Cloud) of the work target. -

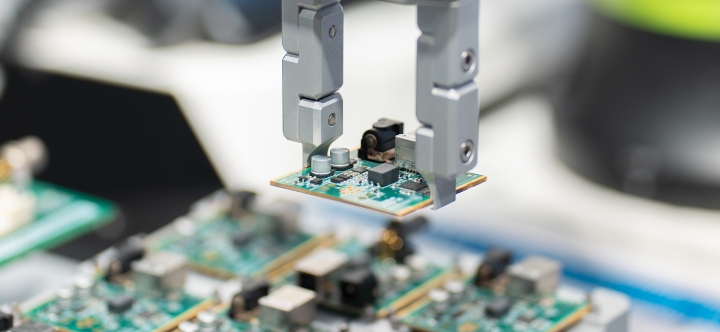

Automatic Calibration

Performs hand-eye calibration that automatically calculates the transformation matrix between sensor and robot with high precision in a short time. -

VRC (Vision-Guided Robot Control)

Transmits 6DoF (6 Degrees of Freedom: 3 position axes, 3 orientation axes) errors of work targets measured by the vision system to the robot controller in real-time, immediately modifying and correcting robot paths. This real-time feedback loop dramatically improves work success rates for irregular objects.

PRINCIPLES

Hand-Eye Calibration & Real-Time Correction

This problem is maximized especially in collaborative robot operating environments where flexibility and ease of use are key.