-

High Dependency on Experts

- High wages & high turnover rates

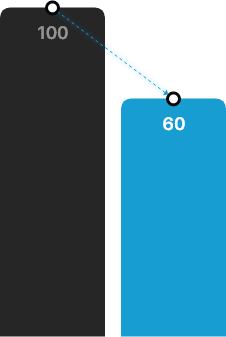

- CNC programmer salaries recently exceed KRW 100 million

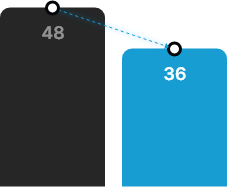

- 61% of robotics engineers change jobs within 2 years

- Shortage of complex robotics specialists

- Training costs over KRW 3 million per week + ongoing retraining

-

Severe Shortage of Skilled Workers

- Few experts possess all required competencies

- Programming tasks concentrated on specific individuals

- Projects halt when key experts are absent

- Extremely high risk for enterprises

-

Excessive Time & Cost

- Process change delay losses: Average KRW 5 million+ per minute

- Process change delays frequently exceed 2-4 weeks

- High initial & maintenance costs (long-term ROI possible)

- Post-automation: Productivity +10-15%, Cost -5-7%

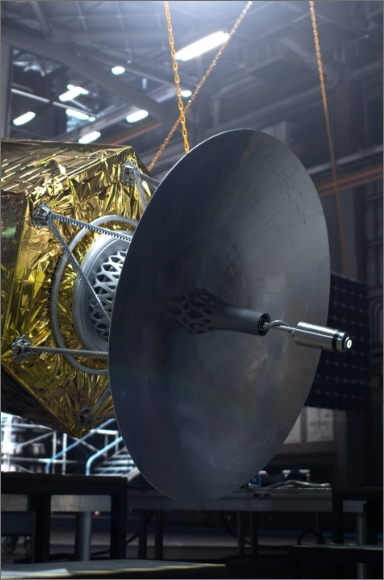

PROBLEMS

Decades of robot manual programming, causing potential loss of hundreds of billions of won per year

In particular, this problem is maximized in the operating environment of cooperative robots, where flexibility and ease of use are key.